Dadi’s and nani’s favourite task is to sew dresses and skirts for their grandkids. A frill here and a bow there, they create masterpieces with their skills and sewing machines.

Sewing has been a part of human life since a long time. 20000 years ago, people used needles made from animal bones to patch up animal sinew and make clothes for themselves. As the humans progressed, a gradual shift from just using threads and needles was observed. Even before the invention of sewing machines, clothing was locally made and was hand sewn. The invention of sewing machine made life easier and faster for the seamstresses and tailors. After the sewing machine was invented, the ready-made clothing industry took off.

INDIGENOUS SWITCHING MACHINE

In India, the sewing machine had been introduced in the late 19th century by the Europeans. But in 20th century, India had introduced its first sewing machine. Bishan Das Basil, a pioneer in Indian engineering industry, perfected the first Indian sewing machine. Basil started as a superintendent of a workshop attached to the central telegraph office and would always be consumed by the Research and Experimental cell. He started devising various equipment that could be used in telegraph and telephone systems.

His endeavours made him realise about the acuteness of Indian technology. He observed the amount of dependency that India had on the foreign countries for the most elementary tools. In 1932 he helped his friend, BK Rohtagi to acquire a patent for manufacturing electric fans which were by the way not made in India at that point of time. Thus the foundation of India Electric works was laid in 1932.

Towards his retirement, Bishan Das Basil, decided to try his hand in entrepreneurship. While going through import statistics he got to know that there were around 60000 pieces of sewing machines that were imported to India in 1934. He converted a room in the staff quarters into a workshop and studied the German Pfaff sewing machine and began devising a prototype for an indigenous sewing machine.

Due to India’s inefficient technology, he had no tools to create a prototype and therefore it took him one year to recreate a mock-up for Indian sewing machine. Another reason for this was that India’s structural engineering growth began with railways, bridges, and steel structures, influencing industries like jute, cotton, coal, and small machine manufacturing. Therefore the tools and workers were concentrated in these sectors only.

Basil invested his two more years and savings into fine tuning the prototype. However, this prototype was very crude in appearance. But despite its crude and unattractive appearance, the machine demonstrated the ability to stitch if handled carefully.

He (Basil) also spent a large sum of Rs. 25000 to hire 75 employees who worked as millers, fitters, assemblers etc to make parts like screws and pins. But still some high precision parts were bought from the Pfaff shops. By the end of 1936,25 machines had been produced and were finally named after the youngest daughter of Bishan Das Basil, Usha.

The USHA sales team did door to door advertising of the sewing machine. This was also the period of strong zeal of patriotism and swadeshi feeling in India. But machine’s technical issues like uneven paint and slow seeing pace hindered it’s sales. Furthermore the uneven alignment of the machine wheels and stand caused frequent jams.

LALA SHRI RAM AND HIS CONTRIBUTION

Lala Shri Ram, an entrepreneur, was impressed by Basil’s courage and tenacity in creating a sewing machine, which required 1,800 operations and required 220 intricate components. Basil’s company, Jay Engineering Works (JEW), was ahead of its time, making the challenge both daunting and thrilling. In 1938, JEW’s board was dissolved, and a new public limited company was formed with Lala Shri Ram, Hans Raj Gupta, M.G Bhagat, and industrialists like Padampat Singhania, KL Poddar, and Karamchand Thapar. A 31-bigha land was purchased in Kolkata, and the company secured new loans and share capital.

ROLE OF WORLD WAR II

By 1939, the company had closed its book with a loss of Rs. 38000. Due to the threat of hostilities from Japan threatened the lives of the workers and therefore the project of USHA sewing machine faced an almost abandonment. The company started producing wartime goods and earned a huge profit.

In 1943, Basil retired from JEW and got a royalty and a sum of Rs. 25000 for new ventures. Jay Engineering Works, despite facing numerous challenges, successfully achieved its production target of 1,000 sewing machines per month in 1947.

Finally USHA was a known brand and fulfilled basic civil needs. It has dominated the market for 8 decades now.

USHA SEWING MACHINE EMPOWERS WOMEN

The USHA sewing machine was a significant empowering tool for women in the 1950s, becoming a popular part of wedding trousseau.

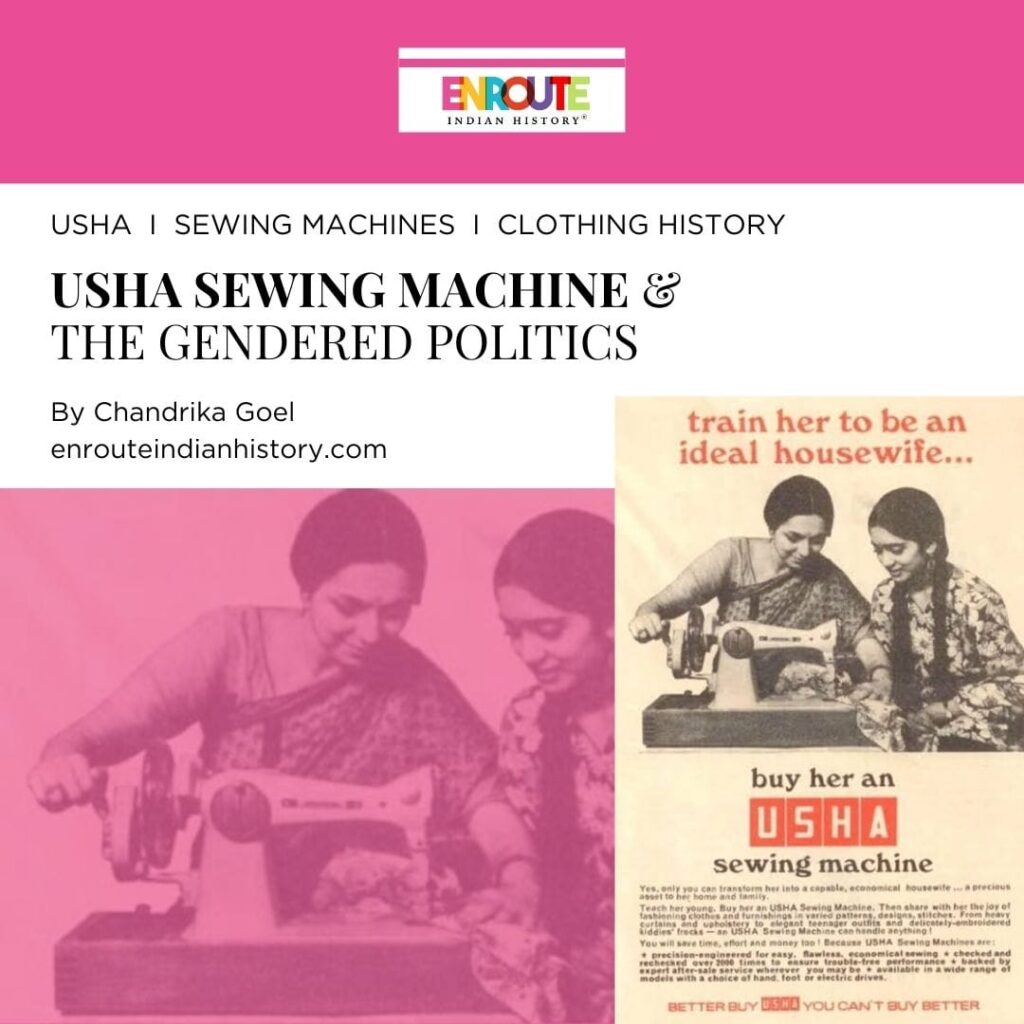

A very famous advertisement portrays a beaming mother-daughter pair sitting across a sewing machine. Bold letters on the ad read, “Train her to be an ideal housewife – buy her an USHA sewing machine.” It empowered women in a sense where they could be independent and work for themselves.

In rural areas, women are taught about sewing and stitching clothes to earn. The company has also come up with different programmes to empower women. For example the USHA silai school programme. Under this programme, women are giving mechanical training on how to repair a sewing machine which is usually considered as a man’s work.

However, people initially had started looking down upon the skill of sewing stitching. But in current times, these skills are coming into main stream and making a name for themselves. The designer boutiques and the sustainable alternative for fast fashion has provided these skills with limelight and importance.

Even today, mothers and grandmothers across the households have a sewing machine stashed in the corners of their room. Using this machine is a skill in itself.

With technological advancement, the USHA sewing machine just gets better and better with built in functions like cross stitching and hemming.

Sewing machines have come a long way since their inception in the early 19th century. Today, they are an essential part of many people’s lives, whether they sew for a living or just for occasional repairs and projects. The USHA sewing machine is one of the most popular and widely used sewing machines on the market. It is known for its durability, versatility, and easy-to-use features. Usha sewing machines are not just practical appliances but also cherished family heirlooms passed down through generations. Each machine is unique and special, reflecting the memories of the first sewing lesson or the family’s involvement in the process. Despite mass production, these classic machines remain in use, showcasing their legacy.

IMAGE SOURCES

- https://www.afaqs.com/news/advertising/55160_from-this-black-and-white-print-ad-to-a-colourful-mumbai-indians-spot

- https://twitter.com/OldIndianAds/status/651627848638201856

- https://www.txantiquemall.com/vintage-pfaff-sewing-machine/

- https://theprint.in/feature/spread-of-railways-wwii-demands-how-usha-sewing-machine-came-to-dominate-indian-markets/1301730/

- https://pin.it/2l4Lf2n

- https://pin.it/4cwH7ZO

- https://pin.it/4E30ud6

BIBLIOGRAPHY

- https://theprint.in/feature/spread-of-railways-wwii-demands-how-usha-sewing-machine-came-to-dominate-indian-markets/1301730/

- https://www.google.com/amp/s/www.huffpost.com/archive/in/entry/how-a-sewing-machine-can-stitch-a-new-story-for-indian-women_b_8029580/amp

- https://www.contrado.co.uk/blog/history-of-the-sewing-machine/#:~:text=People%20started%20sewing%20by%20hand,thread%20made%20from%20animal%20sinew.

- February 22, 2024

- 8 Min Read

- February 16, 2024

- 9 Min Read